Paddle Dryer Manufacturer

Ever wondered how industrial facilities manage to dry heavy sludge, granular materials, or pastes so efficiently? The answer often lies with a paddle dryer manufacturer that specializes in robust, reliable, and energy-efficient solutions. Enter AS Engineers—a company with over two decades of experience in the field of fluid mechanics and drying solutions. If you’re looking for a way to speed up your manufacturing process, cut costs, and ensure consistent product quality, you’re in the right place. In this guide, we’ll reveal everything you need to know about paddle dryers, why AS Engineers excels, and how to choose the perfect system for your needs.

Contact AS Engineers today to get a tailored solution for your facility’s unique drying needs. Our experts are ready to guide you every step of the way!

Why Paddle Dryers Matter

The Industrial Drying Challenge

In many industries, moisture is more than just a nuisance—it’s a roadblock to productivity. Wet sludge, slurry, or granular products can be difficult to handle and may even pose health and safety risks. Uncontrolled moisture can also compromise product integrity, reduce shelf life, and increase shipping costs. That’s where paddle dryers come in. By removing excess water in a controlled, efficient manner, these systems help manufacturers meet quality standards, reduce waste, and comply with strict environmental regulations.

Versatile Applications Across Industries

Whether you’re processing sewage sludge for wastewater treatment or handling delicate food products in a food-processing plant, paddle dryers offer a wide range of applications. Industries like chemical processing, pharmaceuticals, paper and pulp, and metal finishing all benefit from adopting the right drying technology. When done right, drying can be a game-changer:

Consistent Quality: Uniform moisture levels ensure better product performance.

Cost Savings: Reduced transportation costs, lower energy usage, and minimized operational expenses.

Workplace Safety: Less moisture means lower risk of bacterial growth and fewer slippery surfaces in the facility.

Environmental Compliance: Proper sludge drying supports sustainable waste management.

Introducing AS Engineers: Your Trusted Paddle Dryer Manufacturer

AS Engineers has been a pioneer in fluid mechanics and drying solutions for over 23 years. With a track record of delivering robust, tailor-made systems to clients across diverse industries, AS Engineers understands that each application comes with its own set of challenges. Our commitment to quality, innovation, and customer satisfaction has earned us a reputation as a top-notch paddle dryer manufacturer. We also offer an array of other solutions, including centrifugal blowers, axial fans, pollution control equipment, and turnkey project execution.

A Legacy of Excellence

For more than two decades, AS Engineers has pushed the boundaries of industrial engineering:

Expertise in Fluid Mechanics: From blower systems to thermal drying equipment, we’ve built expertise on multiple fronts.

Client-Centric Approach: We don’t believe in one-size-fits-all solutions. Every system is customized based on each customer’s unique operational needs.

Innovation and Research: Our engineering team constantly updates equipment designs, integrating cutting-edge technology and design improvements.

Reliable Support: From the first consultation to the final sign-off—and beyond—we stand behind our products with strong after-sales services and a comprehensive spare parts inventory.

Setting Industry Benchmarks

We’re not just another paddle dryer manufacturer. We take pride in setting industry benchmarks with:

Quality Materials: We use only premium-grade steel and components to ensure durability and longevity.

Energy Efficiency: Our dryers optimize heat transfer to reduce overall power consumption.

Safety Compliance: Every system meets or exceeds international safety standards.

Sustainability Focus: We prioritize environmentally friendly designs to help clients minimize their ecological footprints.

Understanding Paddle Dryer Technology

What Is a Paddle Dryer?

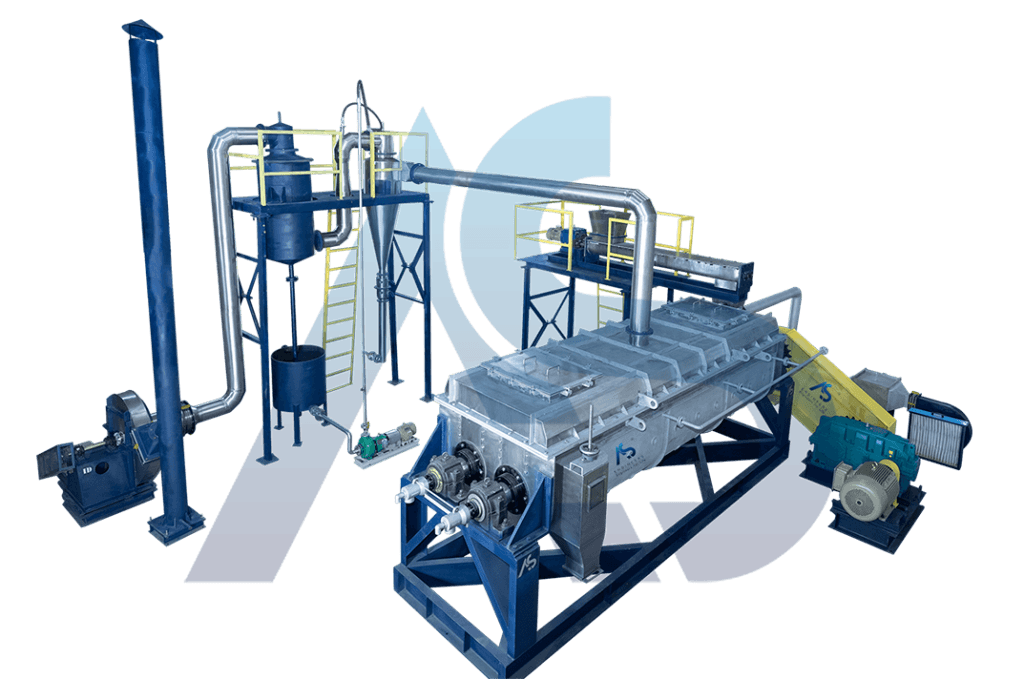

A paddle dryer, sometimes referred to as a sludge dryer or indirect heat dryer, is a thermal drying system that uses rotating paddles fixed to a hollow shaft. The paddles facilitate consistent agitation, ensuring the material comes into contact with the heated surfaces for faster drying. The result is a system that can handle a variety of products—ranging from sticky sludge to granular materials—while maintaining a uniform drying process.

How Does It Work?

Feeding: The wet material enters the dryer through a controlled feeding mechanism.

Heating: Heat is introduced indirectly through hollow paddles and the vessel’s jacket. Steam, hot oil, or hot water circulates through these components.

Mixing: As the paddles rotate, they stir the product, maximizing exposure to the heated surfaces.

Moisture Removal: Moisture vaporizes and is often carried away by a purge gas or vacuum system.

Discharge: The dried material is released through a discharge valve, typically at the opposite end from where it was fed.

Since the drying process is largely indirect, there’s minimal risk of contamination between the heat source and the material. This feature is crucial for applications where product purity is paramount, such as pharmaceutical or food processing.

Key Components and Mechanisms

Rotating Shaft: Houses the paddles and is the primary mixing mechanism.

Paddles: Hollow, wedge-shaped paddles that optimize heat transfer by increasing surface area.

Shell or Vessel: Surrounds the paddles, often designed with a jacket for additional heating or cooling flexibility.

Drive System: Typically includes an electric motor and gear reducer, ensuring precise rotational speed.

Seals and Bearings: Protect sensitive areas from dust ingress and ensure smooth mechanical operation.

The Benefits of Paddle Dryers

Energy Efficiency

With heat transfer rates optimized by the large surface area of the paddles, paddle dryers can significantly cut energy usage. In many cases, they require less steam or hot oil compared to traditional, direct-contact dryers. This energy efficiency not only reduces operational costs but also lowers the plant’s carbon footprint.

Compact Footprint

Compared to older rotary drum dryers, paddle dryers boast a more compact design. Many businesses find this feature invaluable, especially when floor space is at a premium. The slender, horizontal layout can be adapted to fit existing plant configurations without extensive remodeling or structural changes.

Gentle Product Handling

Paddle dryers offer a controlled environment that’s gentler on sensitive materials. Because the paddles operate at relatively low rotational speeds, the mechanical stress on the product is minimal. If you’re working with delicate granules or heat-sensitive materials, this gentle approach can preserve quality.

Minimal Dust Generation

Another advantage is the minimal air or gas flow through the product (if any). This design reduces dust generation and mitigates the risk of product loss or dust explosion hazards. Some installations use a small purge of inert gas (like nitrogen), further reducing contamination risks and enhancing safety.

Consistent Results

Uniform moisture content is crucial for many industries. The robust mixing action ensures every particle receives adequate heat exposure. This consistency translates into better downstream processing, whether it’s packaging, blending, or additional chemical reactions.

How AS Engineers Excels as a Paddle Dryer Manufacturer

1. Custom Design Approach

We start by understanding your material properties—such as density, viscosity, and moisture content. We also consider your production targets, energy sources, and space constraints. After this detailed assessment, our engineers propose a design tailored to your operational goals. This method ensures you never pay for oversized systems or compromise efficiency with underpowered ones.

2. Comprehensive Testing

Before delivering any paddle dryer, we perform rigorous testing:

Material Trials: Small-scale testing to confirm drying rates, ensure final product quality, and validate design assumptions.

Performance Validation: Checking operational parameters like temperature distribution, mixing efficiency, and discharge moisture levels.

Safety Checks: Ensuring compliance with safety norms and identifying any design modifications needed.

3. Energy Optimization

Our design process integrates computational fluid dynamics (CFD) and thermal modeling to optimize heat transfer. By exploring various heating mediums—steam, hot oil, hot water—we can recommend the most energy-efficient solution for your plant. The result is a system that balances speed, efficiency, and capital investment.

4. Integration with Existing Systems

Many of our clients seek upgrades without a full plant overhaul. We excel in integrating paddle dryers into existing setups, whether you have older material-handling conveyors or advanced automation controls. Our engineering team can retrofit the new equipment and ensure seamless communication between your new dryer and the rest of the facility.

5. Commitment to After-Sales Support

Beyond manufacturing, we pride ourselves on offering continuous support. Our after-sales services include:

Installation and Commissioning: Skilled technicians set up the system and verify it under real operating conditions.

Training and Workshops: In-depth sessions for operators and maintenance staff.

Maintenance Packages: Scheduled inspections, performance tune-ups, and fast troubleshooting.

Spare Parts Availability: We maintain a robust inventory of critical components like paddles, seals, and bearings to minimize downtime.

Industries That Benefit from AS Engineers’ Paddle Dryers

Wastewater Treatment: Sludge reduction is critical. Paddle dryers help reduce sludge volume and facilitate disposal or reuse.

Pharmaceuticals: Gentle handling and clean processing environments preserve product integrity.

Food Processing: Precise control over moisture content ensures quality, flavor, and shelf life.

Chemical Manufacturing: Controlled drying for powders, granules, and catalysts.

Paper and Pulp: Efficient handling of fibrous sludge for either disposal or thermal energy recovery.

Mining and Minerals: Drying processes that reduce transportation costs and prepare materials for further refinement.

Metal Finishing: Drying metal sludges to reclaim valuable materials or prep for recycling.

Step-by-Step Guide: How to Choose the Right Paddle Dryer

Selecting a paddle dryer is a strategic investment. Here’s how to navigate the process:

1. Define Your Material Characteristics

Moisture Content: High initial moisture may require more heat or extended residence time.

Particle Size and Shape: Influences the mixing and heat transfer rate.

Flowability: Sticky materials can complicate mixing.

Thermal Sensitivity: Temperature limits must be considered to avoid damaging the product.

2. Estimate Throughput Requirements

Determine your daily or hourly production targets. A mismatch between dryer capacity and production demand leads to inefficiencies—either you’re underutilizing or constantly pushing the system beyond its limits. Work closely with the manufacturer (AS Engineers) to ensure accurate sizing.

3. Decide on the Heating Medium

Common choices include:

Steam: Typically used for its wide availability and quick responsiveness.

Thermal Oil: Offers precise temperature control and uniform heating.

Hot Water: Often used for milder applications with lower temperature requirements.

4. Consider Energy Efficiency

Evaluate factors like heat transfer area, thermal conductivity, and insulation quality. High heat transfer efficiency can drastically cut operational costs over the system’s lifespan.

5. Factor in Maintenance Needs

Look at the complexity of the design. Is the dryer easy to clean, inspect, and service? Are replacement parts readily available? A well-designed paddle dryer simplifies day-to-day operation and ensures long-term reliability.

6. Request a Pilot Test

AS Engineers often arranges pilot-scale trials. This step provides invaluable data on drying rates, energy consumption, and final product quality—letting you fine-tune the full-scale design before committing to major capital expenditure.

7. Analyze Total Cost of Ownership

Beyond the initial purchase price, weigh the operational costs, maintenance expenses, and potential downtime. An efficient, robust dryer may cost more upfront but often proves more economical in the long run.

8. Seal the Deal with a Trustworthy Manufacturer

Check the track record, client testimonials, and service offerings. Choose a paddle dryer manufacturer that delivers end-to-end solutions—from design and testing to installation, training, and spare parts support.

Behind the Scenes: How AS Engineers Designs a Paddle Dryer

Initial Consultation: We analyze your operational challenges, from material specifications to production targets.

Concept Development: Our engineering team creates multiple design concepts, focusing on both mechanical efficiency and cost-effectiveness.

Pilot Testing (If Needed): Small-scale tests validate the proposed design, ensuring drying performance meets expectations.

3D Modeling and Simulation: Using advanced modeling software, we simulate the heat transfer, mixing, and flow patterns.

Manufacturing and Quality Control: Skilled technicians fabricate components, followed by detailed quality inspections.

Factory Acceptance Test: We run the dryer under simulated conditions in our facility to confirm key parameters.

Delivery and Installation: Logistics teams ensure safe transport, and our technical crew oversees installation at your site.

Commissioning and Training: We verify actual performance under real loads and provide operator training to smooth the transition.

Ongoing Support: Maintenance plans, troubleshooting assistance, and a spare parts inventory to keep your system running at peak efficiency.

Maintenance and Operation Best Practices

Proper maintenance extends the life and efficiency of your paddle dryer. Here are some key steps:

Daily Visual Inspection

Look for wear on seals, signs of leakage, or unusual noises. Identifying small issues early prevents costly breakdowns.Lubrication Schedules

The rotating shaft and gear reducers need consistent lubrication. Follow the manufacturer’s recommended intervals to avoid friction and overheating.Temperature Checks

Monitor inlet and outlet temperature to ensure uniform heating. Large deviations could indicate a blockage or malfunction in the heating circuit.Regular Cleaning

Residual buildup reduces heat transfer efficiency and can contaminate subsequent batches. Routine cleaning, especially for sticky or chemical-laden products, is essential.Seal Replacement

Worn seals can compromise the closed-loop design, allowing dust ingress or material leakage. Replace them as needed, paying attention to recommended part numbers or seal materials.Monitor Wear and Tear

Over time, the paddles and the vessel’s interior can wear down, especially if processing abrasive materials. Timely refurbishment or replacement ensures consistent performance.

Myths About Paddle Dryers

Myth 1: “Paddle Dryers Are Only for Sludge Drying”

While sludge drying is a popular use case, paddle dryers can handle everything from crystalline powders to coarse granules. They excel in diverse industries—chemical, food, pharmaceutical, and more.

Myth 2: “They Waste a Lot of Energy”

In reality, paddle dryers can be extremely energy-efficient. They use indirect heating methods and recirculation techniques, significantly lowering energy consumption compared to other drying systems.

Myth 3: “Installation Disrupts Existing Operations”

A well-planned installation can minimize downtime. AS Engineers specializes in integrating new paddle dryers with your existing conveyor systems or automation platforms. Many installations are completed with only minor interruptions.

Myth 4: “Maintenance Is a Hassle”

Routine checks, lubrication, and prompt replacement of wear parts often keep paddle dryers running smoothly. By following a structured maintenance plan, you can dramatically reduce unexpected downtime.

Myth 5: “They Offer Limited Drying Flexibility”

Paddle dryers are actually quite versatile. You can adjust residence time, temperature, and mixing intensity to handle different moisture contents and product properties in one piece of equipment.

After-Sales Services and Spare Parts: AS Engineers’ Commitment

Quick Response Support

Time is money in any manufacturing environment. Our dedicated support team is always prepared to handle troubleshooting calls or on-site visits. Whether you need emergency assistance or routine checks, our experts can guide you through each step.

Extensive Spare Parts Inventory

AS Engineers maintains a well-stocked spare parts inventory to minimize downtime. Core components such as paddles, seals, bearings, and gaskets are readily available. This means you won’t have to wait weeks for critical parts to arrive, ensuring uninterrupted production.

Remote Monitoring & Diagnostics

For modern facilities looking to integrate data analytics, we offer remote monitoring solutions. This technology provides real-time visibility into critical parameters like temperature, torque, and moisture levels. Early detection of anomalies reduces the likelihood of extended downtime or product quality issues.

Technical Training

A well-trained team is essential for maximizing equipment life. We conduct onsite or virtual training sessions covering:

Operation Basics: Understanding system controls and typical operating scenarios.

Maintenance Protocols: Regular inspection routines, lubrication schedules, and part replacement.

Troubleshooting Techniques: Identifying common warning signs and rectifying minor issues before they escalate.

Common Mistakes to Avoid When Operating a Paddle Dryer

Overloading the System

Exceeding recommended throughput can compromise drying efficiency and lead to clumping, uneven moisture removal, or equipment strain.Neglecting Temperature Control

Running at higher temperatures than necessary might speed up drying but risks product degradation, especially in sensitive materials.Ignoring Preventive Maintenance

Delaying routine checks and part replacements often leads to bigger, more expensive problems down the line.Skipping Operator Training

Even the best-designed systems can underperform if operators aren’t properly trained on operational nuances and best practices.Poor Feed Consistency

Feeding vastly different materials or inconsistent moisture levels can result in uneven drying and longer residence times.

Troubleshooting Tips for Common Issues

Inconsistent Product Moisture

Check Feed Rate: Ensure you’re not exceeding capacity.

Adjust Temperature: Fine-tune inlet and outlet temperatures for optimal moisture removal.

Inspect Paddles: Ensure no buildup is hindering effective mixing.

Elevated Power Consumption

Lubricate Bearings: Friction can cause motors to work harder.

Review Heat Source Efficiency: Confirm steam, hot oil, or hot water lines are insulated properly.

Check for Product Buildup: Clogs can force the drive system to use more energy.

Excessive Dust Emissions

Seal Integrity: Inspect sealing components for wear or damage.

Optimize Gas Flow: If using a purge gas, adjust flow rates for minimal product entrainment.

Material Feed Rate: Overfeeding can cause product spillage or dust creation.

Abnormal Vibrations

Balance and Alignment: Check shaft alignment and rotating components.

Wear on Paddles: Uneven wear may cause vibration and hamper mixing efficiency.

Excessive or Unbalanced Material: Confirm the feeder is distributing material evenly.

Frequently Asked Questions (FAQ)

1. How long does it take to install a paddle dryer?

Installation time varies based on the system’s size and complexity. Smaller units can be set up within a week, while large-scale projects with extensive automation integration may take several weeks. Proper pre-installation planning can further streamline the schedule.

2. Can a paddle dryer handle heat-sensitive materials?

Yes. Paddle dryers use indirect heating and low-speed mixing, making them suitable for heat-sensitive materials. You can also fine-tune the operating temperature to minimize any risk of thermal degradation.

3. How do I maintain consistent product quality?

Focus on steady feed rates, appropriate temperature control, and regular equipment inspections. A consistent production process ensures uniform moisture levels, preserving product quality batch after batch.

4. Is it difficult to switch from one material to another?

Switching materials generally involves a thorough cleaning process to avoid cross-contamination. The time required depends on how residue-prone your products are. With careful planning, many facilities manage quick changeovers without significant downtime.

5. Why choose AS Engineers over other paddle dryer manufacturers?

With over 23 years of industry experience, AS Engineers provides customized solutions backed by exceptional after-sales support. Our focus on robust design, rigorous testing, and readily available spare parts ensures a reliable investment with long-term value.

Conclusion

Choosing the right paddle dryer manufacturer can redefine your facility’s drying efficiency, product quality, and operational costs. AS Engineers stands out in this space, leveraging decades of expertise, cutting-edge technology, and a relentless commitment to customer satisfaction. Whether you’re dealing with sludge, powders, or granular materials, our team ensures you get an energy-efficient, customized solution designed to meet your unique production challenges. From consultation to commissioning—and a robust after-sales service that keeps you running at peak efficiency—we’re here to support your growth.

Ready to elevate your drying process? Share your thoughts, questions, or experiences below, and explore our other in-depth guides to learn more about how AS Engineers can help your business succeed.