Thinking about upgrading your industrial heating? An oil fired thermic fluid heater might be just the ticket. These systems are pretty neat because they use special oil to get things hot, way hotter than water can usually handle, and they do it without all the high-pressure headaches that come with steam. Whether you’re making plywood, chemicals, or even food, these heaters can make a big difference in how smoothly things run and how much energy you use. Let’s get into what makes them so useful.

Key Takeaways

- Oil fired thermic fluid heaters work by circulating a special oil through a closed loop to transfer heat indirectly, allowing for higher temperatures at lower pressures compared to steam systems.

- These heaters offer significant benefits like higher operating temperatures, reduced energy consumption due to fewer heat losses, and improved safety because they operate at low pressure.

- Their versatility makes them suitable for a wide range of industries, including plywood and laminate manufacturing, chemical and pharmaceutical processes, textiles, food processing, and bitumen plants.

- Operation is generally straightforward, requiring minimal maintenance and offering flexibility in where they can be installed, even in remote locations.

- When selecting an oil fired thermic fluid heater, consider fuel availability, your specific temperature and flow rate needs, and choose a reputable manufacturer for reliable performance and support.

Table of Contents

Understanding The Thermic Fluid Heater Working Principle

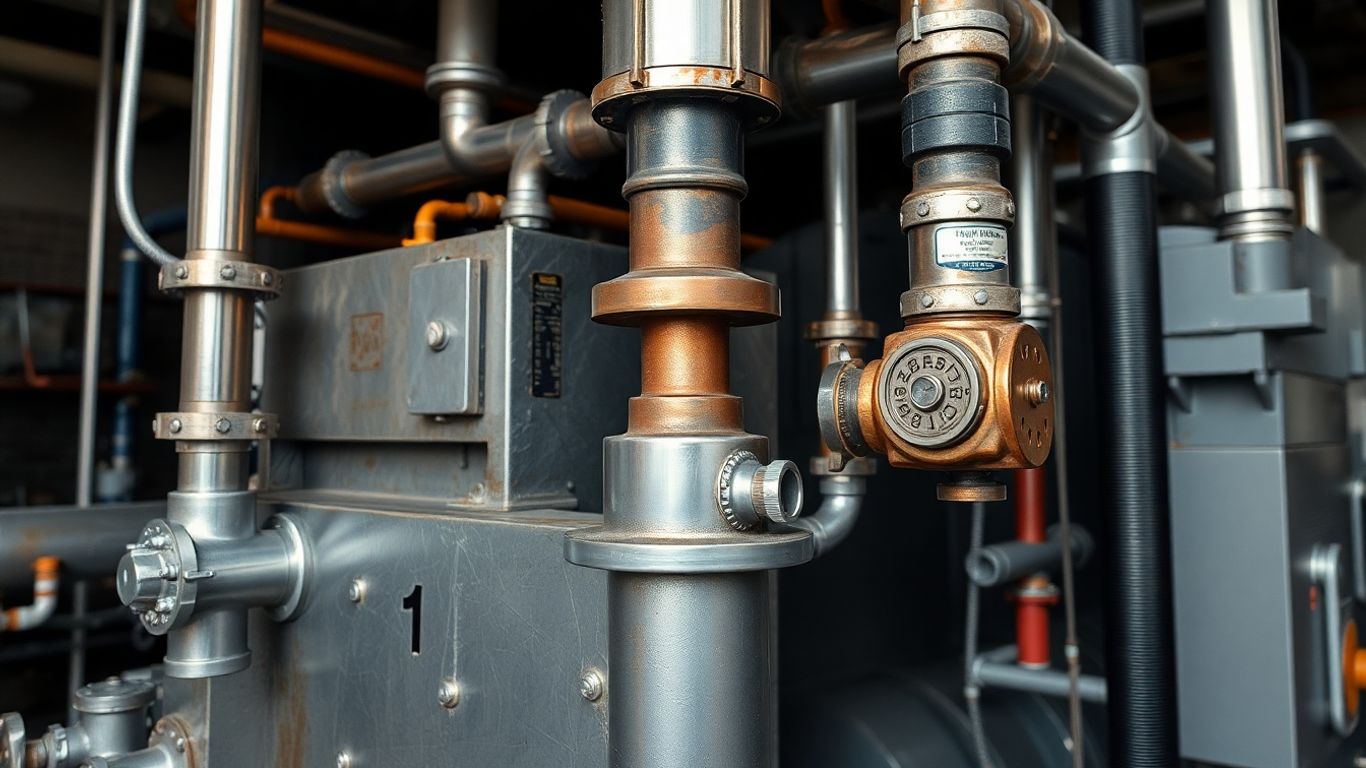

So, how exactly does one of these oil-fired thermic fluid heaters get the job done? It’s actually pretty neat and relies on a principle called indirect heat transfer. Instead of directly heating something with flames or high-pressure steam, it uses a special liquid, often called thermal oil, to move the heat around. This oil gets heated up inside the heater and then circulated to wherever the heat is needed in your plant. It’s a bit like a sophisticated radiator system for your factory.

Indirect Heat Transfer Explained

Think of it this way: you don’t want to scorch your food by putting it directly over a fire, right? You use a pot of water or oil to heat it more evenly. A thermic fluid heater does something similar for industrial processes.

The oil inside the heater absorbs heat from burning fuel, like oil. This heated oil then travels through pipes to your equipment – maybe a press, a dryer, or a reactor. The heat from the oil transfers to your product or process, and then the cooler oil returns to the heater to get warmed up again. This method allows for very precise temperature control, which is a big deal in many manufacturing settings. It avoids the super high pressures that steam systems need, making things a lot safer and simpler.

The Closed-Loop Circulation System

What makes this system really efficient is that it’s a closed-loop. This means the thermal oil stays inside the system. It’s not constantly being added or lost like water might be in a steam boiler. The oil circulates continuously, going from the heater to the process equipment and back again. This closed system has a few big advantages:

- No Fluid Loss: You don’t have to keep topping up the system, which saves on the cost of the thermal fluid itself.

- Reduced Corrosion: Since the oil isn’t exposed to the outside air or contaminants, it’s less likely to corrode the pipes and equipment.

- No Water Treatment Needed: Unlike steam boilers that require careful water treatment to prevent scale and damage, thermic fluid systems are much simpler in this regard.

- Consistent Heat Delivery: Because the oil is always circulating and being reheated, you get a steady supply of heat to your process.

The beauty of a closed-loop system is its self-contained nature. It minimizes external factors that could degrade performance or cause damage, leading to a more reliable and long-lasting operation. This design is key to achieving both high temperatures and operational safety simultaneously.

Key Components of a Thermic Fluid Heater System

While the concept is straightforward, a full system has a few main parts working together:

- Heater Unit: This is where the magic happens. It includes the combustion chamber (where the oil is burned) and the heating coils that transfer the heat to the thermal fluid.

- Circulating Pump: This is the workhorse that keeps the hot thermal fluid moving through the pipes to your equipment and back.

- Expansion Tank: Thermal fluids expand when they get hot. This tank provides a place for the extra volume, preventing pressure buildup.

- Control Panel: This is the brain of the operation, monitoring temperatures, pressures, and safety features to keep everything running smoothly and safely.

- Insulated Piping: Connects all the components, keeping the heat where it needs to be and minimizing energy loss to the surroundings.

Benefits of Oil Fired Thermic Fluid Heaters

When you’re looking at heating solutions for your industrial processes, oil-fired thermic fluid heaters really stand out. They bring a few key advantages to the table that make them a solid choice for many businesses. Let’s break down why they’re so popular.

Higher Operating Temperatures

One of the biggest pluses is their ability to reach higher temperatures compared to traditional steam systems. Thermal oil, the fluid used in these heaters, has a much higher boiling point than water. This means the heater can operate at temperatures up to 750°F (400°C) without building up a lot of pressure. Steam systems, on the other hand, need high pressure to get to those temperatures, which can be a safety concern. This higher temperature capability is great for processes that need that extra bit of heat to get done efficiently.

Reduced Energy Consumption

These heaters are pretty good at saving energy. Because they operate in a closed loop and don’t deal with the heat losses associated with steam systems – like feedwater preheating, blowdown, and steam traps – they tend to use less fuel overall. This efficiency translates directly into lower operating costs and a smaller environmental footprint. Think about it: less wasted heat means less fuel burned, which is a win-win.

Enhanced Safety Features

Safety is always a big deal in industrial settings, and oil-fired thermic fluid heaters have a leg up here too. Since they operate at much lower pressures than steam boilers, the risk of a pressure-related explosion is significantly reduced. This makes them a safer option for your workers and your facility. Plus, the thermal oil itself can have lubricating properties, which helps keep the system running smoothly and reduces the need for constant monitoring or chemical treatments to prevent corrosion. It’s a more stable and predictable heating method.

Versatile Industrial Applications

Oil-fired thermic fluid heaters are showing up in a bunch of different industries, and honestly, it’s not hard to see why. They’re pretty reliable and can handle a lot of different jobs. Let’s break down a few of the places you’ll find them.

Plywood and Laminate Manufacturing

In making plywood and laminates, you need really consistent heat for pressing and coating. Thermic fluid heaters are great for this because they can maintain steady temperatures without a lot of fuss. This means better quality products and less waste. They’re used for things like hot presses and coating lines where that stable surface temperature is a big deal.

Chemical and Pharmaceutical Processes

When you’re dealing with chemicals or pharmaceuticals, precision is key. These heaters are used to warm up reactors, dryers, and distillation units. The ability to control the temperature accurately and operate at lower pressures compared to steam systems makes them a safer choice for handling sensitive materials. This precise temperature control is vital for product integrity and process efficiency.

Textile and Food Processing Sectors

For textiles, thermic fluid heaters are used in drying, curing, and heat-setting operations. In the food industry, they’re found in frying systems, melting processes, pasteurization, and cooking. The indirect heating method means you get clean, food-safe heat, which is obviously super important when you’re making food.

Bitumen and Asphalt Plants

Bitumen and asphalt are thick, sticky stuff that needs to be kept warm to be workable. Thermic fluid heaters are perfect for this, keeping these materials at the right temperature for processing and application. They handle the high temperatures needed without the high pressures that steam systems would require.

Here’s a quick look at where they fit in:

- Plywood/Laminates: Hot presses, coating lines.

- Chemical/Pharma: Reactors, dryers, distillation.

- Textiles: Drying, curing, heat-setting.

- Food Processing: Frying, pasteurization, cooking.

- Bitumen/Asphalt: Keeping materials fluid for processing.

The flexibility of thermic fluid heaters means they can be adapted to many different industrial needs, providing reliable heat without the complexities of high-pressure steam systems. This makes them a practical choice for a wide range of manufacturing and processing operations.

Operational Advantages and Ease of Use

When you’re looking at industrial heating systems, how easy it is to run and maintain them really matters. You don’t want something that’s going to tie up your staff or require constant tinkering. That’s where oil-fired thermic fluid heaters really shine.

Simplified Operation

These systems are designed with simplicity in mind. Unlike steam boilers that deal with high pressures and the complexities of water treatment, thermic fluid systems operate at much lower pressures. This means you don’t need highly specialized operators. Most of the operation can be automated, allowing for scheduled startups and shutdowns based on your production needs. Think of it like this: you set the temperature, and the system handles the rest, maintaining that heat level consistently.

This automation reduces the chance of human error and frees up your team to focus on other critical tasks. The ability to quickly start up and adjust output is a big plus, especially for processes with fluctuating demands. You can get heat to where it’s needed in minutes, not hours.

Minimal Maintenance Requirements

Maintenance is often a big headache with industrial equipment, but thermic fluid heaters are pretty low-maintenance. Because they use a closed-loop system and don’t involve water, you avoid common issues like corrosion and scale buildup. This means no need for daily blowdowns, frequent gasket replacements, or the constant upkeep of steam traps. The thermal fluid itself is also designed for long life, reducing the frequency of fluid replacement. This translates directly into lower maintenance costs and less downtime. It’s a system that just keeps running with basic checks, rather than demanding constant attention. For industries like textile manufacturing, where consistent heat is key, this reliability is a huge benefit.

Flexibility in Installation

Another great thing about these heaters is how flexible they are when it comes to where you can put them. Since they’re indirect heating sources and don’t have the same pressure concerns as steam, you can install them in a variety of locations. Need to put the heater a bit away from your main process area? No problem. They can be installed outdoors without needing special freeze protection, which can save valuable indoor space. Their design often allows for both horizontal and vertical configurations, fitting into different plant layouts.

Some units even come pre-assembled on skids, making installation much quicker and simpler, especially if you’re working with limited space or retrofitting an existing facility. This adaptability means you can place the heat source exactly where it’s most efficient for your specific application, whether that’s in chemical processing or food production.

Cost-Effectiveness of Thermal Fluid Systems

When you’re looking at industrial heating, the price tag is always a big deal, right? You want something that works well without breaking the bank. That’s where oil-fired thermic fluid heaters really shine. They’re not just about getting things hot; they’re about doing it smart and saving you money in the long run.

Lower Capital Investment

Compared to some other heating setups, especially those involving high-pressure steam, getting a thermic fluid system up and running can be less of an upfront hit to your wallet. You don’t need all the heavy-duty, high-pressure rated piping and complex safety gear that steam systems often demand. This means less material cost and potentially quicker installation, which also cuts down on labor expenses. It’s a more accessible way to get into efficient, high-temperature heating.

Reduced Operating Expenses

This is where the real savings start to add up. Thermic fluid systems are known for being pretty efficient. They operate in a closed loop, meaning the heating fluid just keeps circulating and doesn’t get lost through phase changes like steam does. This means less energy is wasted. Plus, because they don’t need constant water treatment to fight corrosion and scale like steam boilers do, you save on chemicals and the labor to manage them. The system itself also tends to last longer with fewer breakdowns, meaning less downtime and fewer repair bills. It’s a win-win for your operational budget.

Fuel Savings Compared to Steam

Here’s a specific area where oil-fired thermic fluid heaters really beat steam. Think about all the places steam can lose heat: leaky traps, the need for constant blowdown to remove impurities, and preheating feedwater. Thermic fluid systems sidestep all of that. They operate at higher temperatures without needing the extreme pressures that steam requires, which is a huge energy saver. Studies show these systems can offer up to 20% in fuel savings compared to steam heating. That’s a significant chunk of change back in your pocket over time, especially with fluctuating fuel prices. For many industrial processes, these systems are a more economical choice for consistent heat transfer.

The efficiency of a thermic fluid system comes from its ability to maintain a consistent temperature without the energy losses associated with phase changes or high-pressure operations. This single-phase operation, combined with precise temperature control, directly translates into lower energy consumption and, consequently, reduced operational costs over the lifespan of the equipment.

Here’s a quick look at why they save money:

- No Steam Losses: Avoids heat loss from steam traps, blowdown, and feedwater preheating.

- Lower Pressure Operation: Reduces the need for expensive, high-pressure components and associated maintenance.

- Efficient Heat Transfer: The thermal fluid itself is designed for efficient heat transfer, minimizing energy waste.

- Reduced Maintenance: Less downtime and fewer repair costs due to fewer corrosion and scaling issues compared to steam.

Choosing the Right Thermic Fluid Heater

So, you’re looking to get a thermic fluid heater for your plant. That’s a smart move, they really do a good job with consistent heat. But picking the right one can feel a bit overwhelming with all the options out there. Don’t worry, we’ll break it down.

Assessing Fuel Availability

First things first, what kind of fuel do you have easy access to, and what makes the most sense for your budget? Oil-fired heaters are popular because they’re pretty common, but you might also consider natural gas, LPG, or even solid fuels if that’s more practical for your location. It really depends on what’s readily available and cost-effective for your specific setup. Fuel flexibility is a big plus, allowing you to adapt if fuel prices change.

Matching Temperature and Flow Rate Needs

Next, you need to figure out exactly how much heat you need and how quickly. Think about the highest temperature your process requires and the volume of fluid you’ll be moving. This isn’t just a guess; it’s about matching the heater’s capacity to your actual workload. Getting this wrong means either you don’t have enough heat, or you’ve got a system that’s way too big and inefficient. It’s important to consider your thermal load carefully.

Here’s a quick look at how different factors play a role:

| Factor | Consideration |

|---|---|

| Max Process Temp | Heater must exceed your highest requirement. |

| Flow Rate | Needs to match the volume of fluid circulation. |

| Heat-up Time | How quickly do you need to reach operating temp? |

| Continuous vs. Batch | Does your process run non-stop or in cycles? |

Selecting a Trusted Manufacturer

Finally, who are you buying from? This is super important. You want a manufacturer with a good reputation, one that makes reliable equipment and has solid support. Think about their track record, what kind of warranty they offer, and if they can provide technical help when you need it. A good manufacturer will also guide you on choosing the right thermal heating fluid for your system, which is just as critical as the heater itself. For instance, some manufacturers offer custom-engineered solutions to fit your exact needs, which can be a real game-changer.

Picking the right thermic fluid heater is about balancing your process needs with available resources and reliable equipment. Don’t rush this decision; it’s an investment that impacts your operations for years to come.

Wrapping Up: Why an Oil-Fired Thermic Fluid Heater Makes Sense

So, after looking at all this, it’s pretty clear that an oil-fired thermic fluid heater is a solid choice for a lot of industrial jobs. They can get things really hot, but without all the high-pressure headaches you get with steam. Plus, they don’t need as much fussing over – less water treatment, fewer parts to break, and generally easier to run. When you’re picking one out, just think about what fuel you have, how hot you need it, and what you’re using it for. Getting a good quality unit from a company that knows their stuff will make a big difference in the long run. It’s about getting reliable heat, safely, and without breaking the bank on upkeep.

Frequently Asked Questions

How does an oil-fired thermic fluid heater work?

It’s like a special kind of oven for factories. You burn oil to heat up special oil inside coils. This hot oil then travels through pipes to heat up whatever the factory needs, like machines or vats. After it gives off its heat, the cooler oil comes back to the heater to get hot again, making a continuous loop.

Why are these heaters better than steam boilers?

Think of it this way: steam needs really high pressure, which can be dangerous and needs lots of checks. Thermic fluid heaters work at much lower pressures, making them safer. Plus, they can get hotter than steam and don’t need as much upkeep, like constant water treatment or fixing leaks.

Can these heaters be used in many different industries?

Absolutely! They’re super useful. Factories that make wood panels, chemicals, medicines, clothes, and even food use them. They’re great for anything that needs steady, high heat, like drying things, cooking, or keeping sticky stuff like asphalt warm so it can be moved.

Are they hard to operate and maintain?

Not at all! They’re designed to be pretty simple to run, so you don’t need a super-specialized person to manage them. And because they don’t use water like steam boilers, there’s less rust and fewer parts to break, meaning less fixing and cleaning.

Are they expensive to buy and run?

Actually, they can be more affordable in the long run. While the first cost might be similar, they often use less energy than steam systems. Plus, with less maintenance needed, your day-to-day costs go down too.

What should I think about when picking one?

First, check what kind of fuel is easy for you to get, like oil or gas. Then, figure out how hot you need things to get and how much of that hot oil you’ll need. It’s also smart to pick a company that’s known for making good, reliable heaters and has good support if you need help.