When it comes to keeping industrial operations running smoothly, the right heating equipments for industries are absolutely key. We’re talking about the big stuff here, the systems that provide the heat needed for everything from manufacturing to keeping large spaces comfortable. This guide is all about breaking down the different types of heating systems you’ll find in industrial settings, what makes them tick, and how to make sure they’re working their best. Think of it as a rundown of the essential gear that powers a lot of what goes on behind the scenes in factories and large buildings.

Key Takeaways

- Steam boilers are central to industrial heating, generating steam for a wide range of processes and applications.

- Different types of boilers, like fire-tube, water-tube, and electric, offer various benefits for specific industrial needs.

- Controlling pressure and maximizing heat transfer are vital for efficient and effective steam boiler performance.

- Safe operation, including proper start-up, shutdown, and regular maintenance, is critical for boiler longevity and preventing accidents.

- Industrial heating solutions extend beyond steam, encompassing electric heaters for air, space, and process heating, including specialized explosion-proof models.

Table of Contents

Understanding the Core of Industrial Heating: Steam Boilers

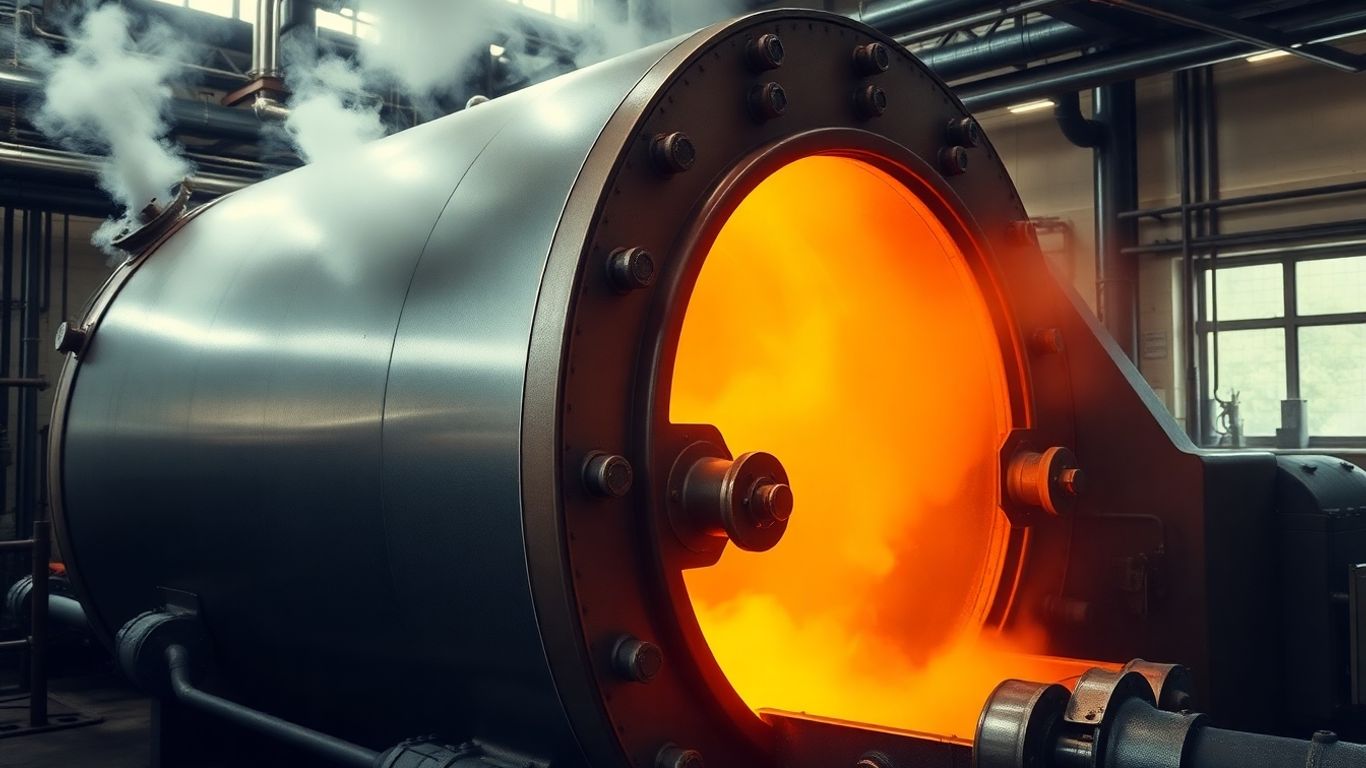

Steam boilers are pretty much the engine room for a lot of industries. They’re the machines that take fuel and turn it into steam, which is then used for all sorts of heating and processing tasks. Think of them as the heart of the operation, pumping out the heat needed to get things done.

Definition and Fundamental Functions of Industrial Boilers

At its simplest, a boiler is a piece of equipment that heats water to make steam or hot water. It does this by burning fuel, like natural gas, oil, or even solid fuels, and transferring that heat to the water inside a sealed vessel. This steam is then piped out to wherever it’s needed. The main job is to convert the energy from the fuel into usable thermal energy in the form of steam. It’s a pretty straightforward concept, but the engineering behind it is quite involved to make sure it’s safe and efficient.

The Indispensable Role of Steam Boilers Across Industries

Seriously, so many places rely on steam boilers. In manufacturing, they’re used for everything from drying products to powering machinery. The chemical industry uses them for reactions and distillation. Food and beverage companies need steam for pasteurization and sterilization. Even in large buildings, steam boilers can be used for heating. The versatility of steam as a heat transfer medium is what makes these boilers so important. It can carry a lot of heat and be controlled quite precisely, which is a big deal when you’re dealing with sensitive processes. You can find more details on their applications in industrial heating solutions.

Key Components and Operational Principles of Steam Boilers

So, how does a steam boiler actually work? It’s a system with several key parts working together. You’ve got the burner, which mixes fuel and air to create a flame. Then there’s the heat exchanger, where the hot gases from the flame pass over or through tubes filled with water, transferring heat. The steam drum is where the steam collects before it’s sent out. There are also control systems to manage pressure and temperature, and safety features to prevent problems.

Here’s a quick rundown of the main parts:

- Burner: Where the fuel is ignited.

- Heat Exchanger: The area where heat moves from the combustion gases to the water.

- Steam Drum: Collects the steam produced.

- Water Drum: Supplies water to the boiler.

- Safety Valves: Release excess pressure.

The whole process relies on getting heat into the water efficiently and safely. It’s a balance of combustion, heat transfer, and pressure management to produce the steam needed for various industrial tasks.

Operating a steam boiler involves careful attention to pressure. The pressure inside the boiler is what allows the water to get hotter than its normal boiling point, making the steam more energy-dense. Maintaining the correct pressure is vital for both efficiency and safety. Too low, and you don’t get enough heat; too high, and you risk dangerous situations. It’s a delicate balance that operators must manage.

Exploring Different Types of Industrial Steam Boilers

When you’re looking at industrial heating, you’ll find there isn’t just one kind of steam boiler. They’ve come up with different designs to handle all sorts of jobs and pressures. It’s kind of like choosing the right tool for a specific task – you wouldn’t use a hammer to screw in a bolt, right? The main types you’ll run into are fire-tube, water-tube, and electric boilers. Each has its own way of working and is better suited for certain situations.

Fire-Tube Boilers: Design and Applications

Fire-tube boilers are one of the older, more traditional designs. The basic idea here is that hot gases from burning fuel travel through tubes that are surrounded by water. Think of it like a big kettle with pipes running through it. The heat from the gases transfers to the water, making steam. They’re generally simpler to build and maintain, which can make them a bit cheaper upfront.

- Design: The combustion gases pass through a set of tubes, and the water is on the outside of these tubes. The boiler shell contains both the tubes and the water.

- Pressure Limits: Because the shell has to contain all the water and steam pressure, fire-tube boilers usually have limits on how high the pressure can go. They’re typically used for lower to medium pressure applications.

- Applications: You’ll often find these in smaller industrial settings, for heating buildings, or in processes that don’t need super high-pressure steam. They’re good for quick start-ups and can handle fluctuating steam demands pretty well.

Water-Tube Boilers: Efficiency and Versatility

Water-tube boilers flip the script. In this design, the water is inside the tubes, and the hot combustion gases flow around the outside of the tubes. This setup allows for a much larger surface area for heat to transfer from the gases to the water. This is a big reason why water-tube boilers are generally more efficient and can handle much higher pressures than fire-tube boilers.

- Design: Water circulates through a network of tubes, and these tubes are heated by the combustion gases in a larger furnace area.

- High Pressure Capability: The tubes are designed to withstand high pressures, and the overall construction allows for very large steam generation capacities.

- Applications: These are the workhorses for heavy-duty industrial applications. Think power plants, large chemical facilities, refineries, and anywhere that needs a lot of high-pressure steam reliably. They can be configured in various ways, like D-style, O-style, or A-style, depending on the specific layout and space.

Electric Boilers: A Modern Alternative

Electric boilers are a bit different because they don’t burn fuel at all. Instead, they use electricity to heat the water. This means they don’t produce any emissions right at the boiler itself, which is a pretty big deal for places that need to keep their local air quality clean or have strict environmental rules.

- Operation: They typically use electric resistance heating elements submerged in the water. When electricity flows through these elements, they get hot and transfer that heat to the water, turning it into steam.

- Advantages: They’re known for being highly efficient in converting electricity to heat, they’re quiet, and they have a compact design. They also offer very precise temperature control.

- Considerations: The main drawback is that their operating cost depends heavily on electricity prices, which can sometimes be higher than fuel costs. They’re also limited by the available electrical supply. These are often used for smaller-scale operations or in specific applications where their benefits outweigh the cost.

Choosing the right type of boiler really comes down to what you need it to do. You have to think about how much steam you need, what pressure it has to be at, how quickly you need it, and what your fuel or energy source options are. It’s not a one-size-fits-all situation.

Optimizing Performance: Efficiency and Pressure in Steam Boilers

When you’re running an industrial operation, getting the most out of your heating equipment isn’t just about comfort; it’s about keeping costs down and making sure everything runs smoothly. For steam boilers, this really comes down to two big things: how efficiently they use fuel and how well they manage pressure. It’s not rocket science, but it does take some attention to detail.

Think of pressure as the engine that drives your steam. Water boils at 212°F (100°C) normally, right? But crank up the pressure inside the boiler, and that boiling point goes up. This means the steam you get is hotter and carries more energy. This extra heat is what makes steam so useful for all sorts of industrial jobs, from driving turbines to heating up vats of chemicals. Keeping that pressure steady and at the right level is key. Too low, and your steam won’t have enough oomph. Too high, and you run into safety issues. It’s a balancing act.

Maximizing Heat Transfer for Enhanced Efficiency

So, how do we make sure all that fuel energy actually turns into useful steam without a ton of waste? It’s all about heat transfer. The goal is to get as much heat as possible from the burning fuel into the water. Things like:

- Boiler Design: The way the tubes and surfaces are arranged inside the boiler makes a big difference in how well heat moves.

- Insulation: Good insulation keeps the heat where it belongs – in the water – instead of escaping into the boiler room.

- Cleanliness: Soot on the fire side or scale on the water side acts like a blanket, blocking heat. Keeping these clean is a must.

The better the heat transfer, the less fuel you burn for the same amount of steam.

Strategies for Improving Boiler Efficiency

Beyond just keeping things clean, there are other ways to squeeze more efficiency out of your boiler. It’s about being smart with your resources.

- Proper Sizing: Make sure your boiler is the right size for the job. An oversized boiler will cycle on and off too much, which isn’t efficient. An undersized one will struggle to keep up.

- Combustion Control: Fine-tuning the air-to-fuel mix is super important. Too much or too little air can waste fuel and create harmful byproducts.

- Heat Recovery: Sometimes, you can capture waste heat from the exhaust gases and use it to preheat the incoming water. This is like getting free energy!

Keeping your boiler running efficiently isn’t a one-time fix. It requires regular checks and adjustments. Think of it like maintaining a car; regular tune-ups prevent bigger, more expensive problems down the road and keep it running at its best. Paying attention to these details can really add up in savings and reliability for your whole operation.

Essential Considerations for Industrial Boiler Operation

Operating industrial boilers isn’t just about flipping a switch and letting them run. There’s a real need for careful attention to detail to keep things running smoothly and, more importantly, safely. Think of it like driving a car – you wouldn’t just ignore the dashboard lights or skip oil changes, right? Boilers are similar, but with much higher stakes.

Safe Start-up and Shutdown Procedures

Getting a boiler online or taking it offline needs a specific sequence of actions. Rushing these steps can cause all sorts of problems, from thermal shock that can crack metal to incomplete combustion that wastes fuel. It’s all about gradual changes.

- Start-up: This usually involves checking water levels, purging the system of air, and then slowly bringing up the heat and pressure. You’ll want to monitor gauges closely during this phase.

- Shutdown: The reverse is true here. You need to reduce the heat and pressure gradually, making sure the boiler cools down evenly. This prevents stress on the metal components.

- Post-Shutdown Checks: After it’s off, a quick inspection can catch issues before they become bigger problems.

Proper procedures aren’t just about following rules; they’re about preventing damage and ensuring the equipment lasts as long as it should. It’s a proactive approach to maintenance.

Crucial Safety Precautions for Boiler Operation

Safety is really the top priority. These machines operate under high pressure and temperature, so any mistake can have serious consequences. Always follow the manufacturer’s guidelines and your facility’s safety protocols.

- Pressure and Temperature Limits: Never exceed the boiler’s rated pressure or temperature. This is what safety valves are for, but they are a last resort, not a normal operating condition. Keep a close eye on your pressure gauges.

- Water Level: Maintaining the correct water level is vital. Too low, and you risk overheating and damaging the boiler tubes. Too high, and you can get water carryover into the steam lines, which is bad for downstream equipment.

- Safety Devices: Regularly check that safety valves, low-water cutoffs, and pressure controls are functioning correctly. These are your primary safety nets.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, like safety glasses and gloves, when working near an operating boiler.

Regular Maintenance for Optimal Performance

Boilers, like any complex machinery, need regular check-ups to perform at their best and avoid unexpected breakdowns. Think of it as preventative care.

- Inspections: This includes visual checks for leaks, corrosion, or damage, as well as more in-depth internal inspections periodically.

- Cleaning: Soot buildup on the fireside and scale on the waterside both reduce heat transfer efficiency and can cause overheating. Regular cleaning is a must.

- Water Treatment: Proper water treatment is key to preventing scale and corrosion, which are major enemies of boiler longevity and efficiency. This involves regular testing of water chemistry.

- Component Checks: Regularly inspect and test pumps, valves, burners, and control systems to ensure they are working as they should. A small issue ignored can quickly become a major repair.

| Maintenance Task | Frequency (Typical) | Notes |

|---|---|---|

| Water Quality Testing | Daily/Weekly | Adjust chemical treatment as needed |

| Safety Valve Test | Monthly/Quarterly | Ensure proper operation |

| Burner Cleaning | Annually | Optimize combustion efficiency |

| Internal Inspection | Annually/Biennially | Check for scale and corrosion |

| External Cleaning (Soot) | As needed | Improve heat transfer |

Diverse Applications of Industrial Heating Equipments

Industrial heating equipment is incredibly varied, and its applications stretch across so many different sectors. It’s not just about keeping a factory warm; it’s about powering entire production lines and making sure specific processes happen just right. Think about it – from making food safe to eat to creating the medicines we rely on, heat is a constant requirement.

Powering Manufacturing and Chemical Processes

In manufacturing and chemical plants, steam boilers are often the workhorses. They provide the consistent heat needed for all sorts of things. For example, in food processing, steam is used for pasteurization and sterilization, making sure products are safe. The textile industry uses steam for dyeing and drying fabrics, which needs precise temperature control. Even in pharmaceuticals, where quality is super important, steam helps maintain the exact conditions needed for making drugs. It’s pretty amazing how much these systems do behind the scenes. Many of these processes rely on reliable industrial heating elements to function correctly.

- Chemical Reactions: Providing controlled heat for synthesis and other reactions.

- Drying and Curing: Removing moisture from products or setting coatings.

- Sterilization: Killing microorganisms in food, medical supplies, and equipment.

- Distillation: Separating components of a liquid mixture using heat.

The ability of steam to carry a lot of heat and deliver it efficiently makes it a go-to for many industrial tasks. It’s a versatile medium that can be managed to meet very specific temperature and pressure needs.

Specialized Low-Pressure Steam Applications

While we often think of high-pressure steam, there are many situations where lower pressure is actually better. These systems are used when intense heat isn’t necessary, or when delicate materials are involved. Think about cleaning and sanitizing in hospitals, or maintaining specific humidity levels in places like greenhouses or data centers. Low-pressure steam offers a gentler, more controlled way to achieve these goals without the risk of damaging sensitive items or using more energy than needed.

- Humidification in controlled environments.

- Gentle cleaning and sterilization in healthcare.

- Specific drying processes for sensitive materials.

Commercial and Comfort Heating Solutions

Beyond the factory floor, steam heating systems are also used for warming up large commercial spaces. This includes things like shopping malls, large office buildings, and even some residential complexes. Steam circulates through pipes to radiators, distributing heat evenly throughout the space. It’s a well-established method for keeping large areas comfortable, especially in older buildings where it might be the most practical heating solution. These systems need regular checks to make sure they’re working efficiently and providing consistent warmth.

Advanced Industrial Electric Heating Solutions

When steam boilers aren’t the best fit, or you need a more targeted approach, electric heating systems really shine. They offer a lot of flexibility and can be a great choice for specific industrial jobs. We’re talking about heating air, liquids, and even creating safe heating in really tricky spots.

Electric Air and Large Space Heaters

These are your go-to for warming up big areas or specific zones within a factory or commercial building. Think warehouses, loading docks, or even large workshops where consistent, reliable heat is a must. They’re built tough, designed to handle industrial settings, and can be used for all sorts of tasks. Need to keep metal warm before welding? Dry off some concrete? Or just make a huge space a bit more comfortable for folks working there? These heaters can do it. Some are even designed to work with existing HVAC systems to give them a boost.

- Durable construction for tough environments.

- Can be used for comfort heating or process-specific tasks.

- Options available for augmenting existing HVAC.

Electric Immersion Heaters

If you need to heat liquids or gases directly, immersion heaters are the way to go. They get dropped right into the tank or vessel, making them super efficient. They’re used everywhere, from food processing to mining operations. The main job is keeping liquids at a very specific temperature, which is important for a lot of chemical reactions or storage needs. You can get them with different hookups, like screw plugs or flanges, so they fit into whatever setup you have. They provide direct, efficient heat transfer.

Here’s a quick look at how they work:

- Element Insertion: The heating elements are submerged directly into the fluid.

- Electrical Resistance: Electricity flows through the elements, generating heat.

- Heat Transfer: The heat is directly transferred to the surrounding liquid or gas.

- Temperature Control: Thermostats or sensors maintain the desired temperature.

Explosion-Proof Industrial Electric Heaters

Now, this is where things get serious. In places where flammable gases or vapors might be around, you can’t just use any old heater. That’s where explosion-proof heaters come in. They’re built with extra safety features to prevent sparks or overheating that could cause a disaster. These are often used in chemical plants, refineries, or anywhere you have hazardous locations. They’re designed to contain any potential ignition source. Safety is the absolute top priority with these units.

These heaters are specifically engineered to operate safely in environments where flammable materials are present. They use special designs and materials to prevent any internal or external component from igniting the surrounding atmosphere. This makes them indispensable for maintaining operational temperatures in hazardous zones without compromising safety protocols.

Wrapping Up: Keeping Your Industrial Operations Warm and Running

So, we’ve covered a lot about the heating equipment that keeps industries humming. From the big steam boilers that power so many processes to the electric heaters keeping spaces comfortable, it’s clear these systems are really important. Picking the right gear, whether it’s for making steam or just warming up a warehouse, makes a big difference in how well things run. Keeping up with maintenance and making sure everything is safe is key, too. Think of it like taking care of your car – a little attention goes a long way in preventing bigger headaches down the road. Ultimately, having the right heating setup means your business can keep producing, stay efficient, and keep everyone comfortable.

Frequently Asked Questions

What exactly is a steam boiler and what does it do?

Think of a steam boiler as a big, strong metal tank. Its main job is to heat water until it turns into steam. This steam is then used for many things in factories, like heating up other machines or helping to make products.

Why are steam boilers so important in factories?

Steam boilers are super important because they provide a lot of heat energy. Many factory jobs, like cooking food, making chemicals, or even drying things, need this consistent heat. Without steam boilers, many factories couldn’t do their work.

What are the main parts of a steam boiler?

A steam boiler has a few key parts. There’s a burner that burns fuel to make heat, a part where the water gets heated (like a special metal box), and a tank where the steam collects. There are also important controls to keep everything working safely and just right.

Are there different kinds of steam boilers?

Yes, there are! Some boilers have the hot gases pass through tubes surrounded by water (fire-tube boilers). Others have water flowing through tubes that are heated by the fire (water-tube boilers). There are also electric boilers that use electricity to heat the water, which are a more modern option.

How does pressure help a steam boiler work better?

Pressure is like the engine for the steam. When you heat water under pressure, it can get much hotter than regular boiling water. This super hot steam can carry more energy, making it really good for heating things up quickly and efficiently in the factory.

What’s the best way to keep a steam boiler working well and safely?

It’s really important to follow the rules! You need to start and stop the boiler carefully. Always wear safety gear and make sure the boiler is checked regularly. Keeping it clean and fixing any small problems right away helps it last longer and work its best.